Tag Archive for: Steel Ball Manufacturing Mill

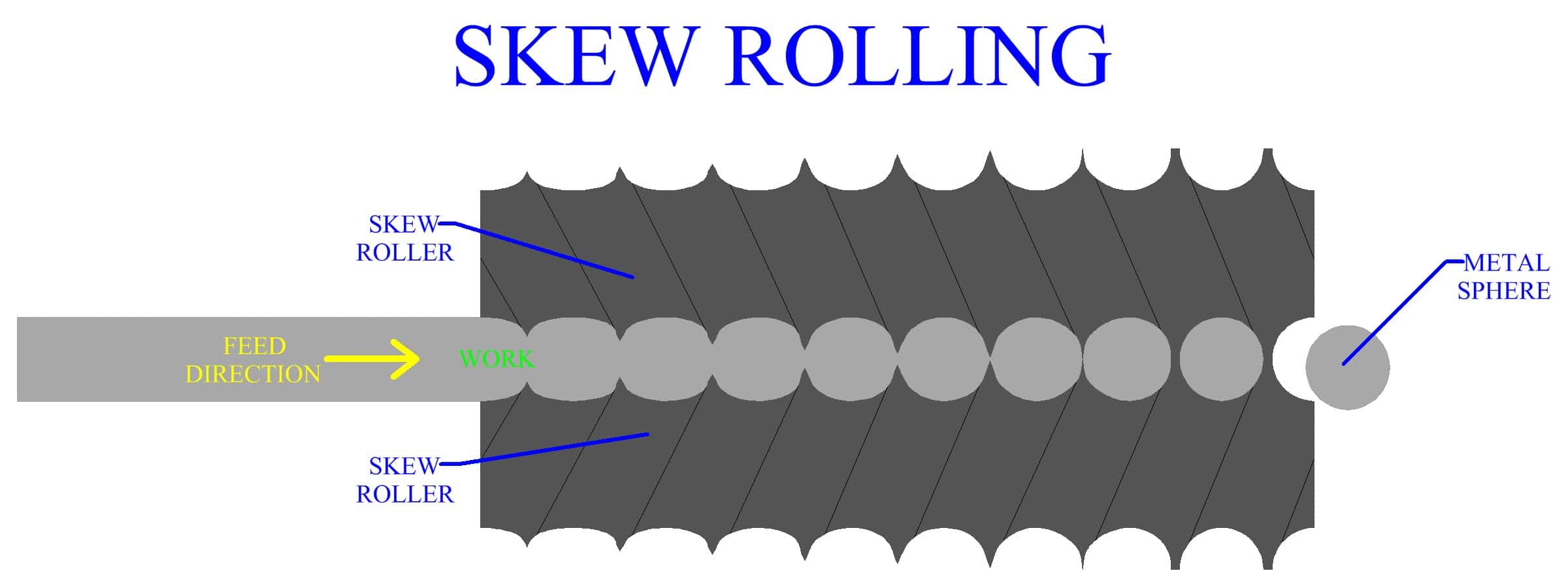

skew rolling process and how it works?

Skew rolling is a metal forming process that is typically used…

What are the advantages of skew rolling machine?

Skew rolling machines have several advantages including: 1.…

The Working principle of grinding steel ball production line

The grinding steel ball production line is a process that involves…

What is skew rolling process?

Skew rolling is a metalworking process used to form balls or…