The working principle of a wear-resistant steel ball skew rolling mill

Skew rolling mills are a kind of steel ball making machine specially designed for the grinding industry.

The working principle of a wear-resistant steel ball skew rolling mill is as follows:

1. Heating process: In the working process of the wear-resistant steel ball skew rolling mill, the steel billet needs to be heated first. Steel billets are usually heated in a high-frequency induction furnace until they reach a suitable rolling temperature. The heated billets are descaled before being sent into the rolling mill, removing surface iron oxide scales.

skew rolling mill feed rod

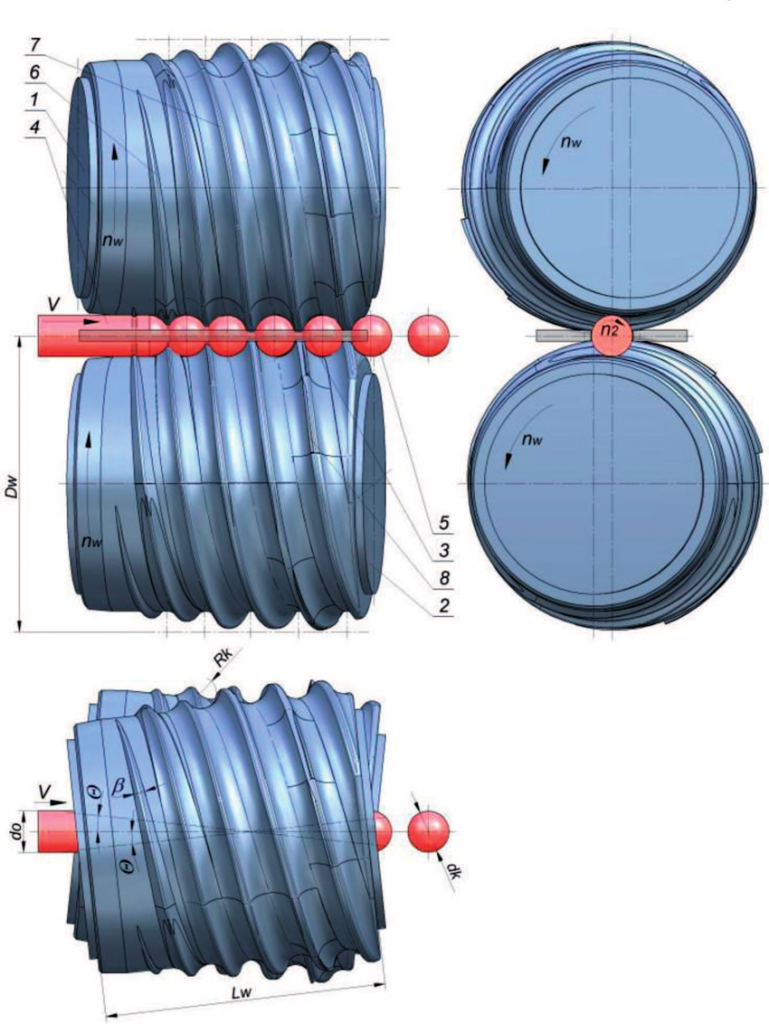

2. Skew rolling forming process: The heated and descaled billets are sent into the skew rolling mill. The skew rolling mill consists of two opposing skew-arranged rollers. When the billet enters between the two rollers, due to the inclination and rotation of the rollers, the billet will be stretched and squeezed to form a nearly spherical shape. This process is also known as “pressure deformation.”

3. Ball shaping and cooling: The steel balls rolled by the skew rolling mill will have some deviation in shape and size. In order to obtain steel balls with precise dimensions and a smooth surface, a correction process is usually performed. After correction, the steel balls will be sent to cooling equipment for cooling, which reduces their temperature and enhances their hardness.

4. Inspection and sorting: The cooled steel balls need to undergo quality checks, including appearance, hardness, wear resistance, etc. The qualified steel balls will be sorted out and packaged before being sent to the warehouse. The unqualified steel balls will be returned for remelting and rerolling.

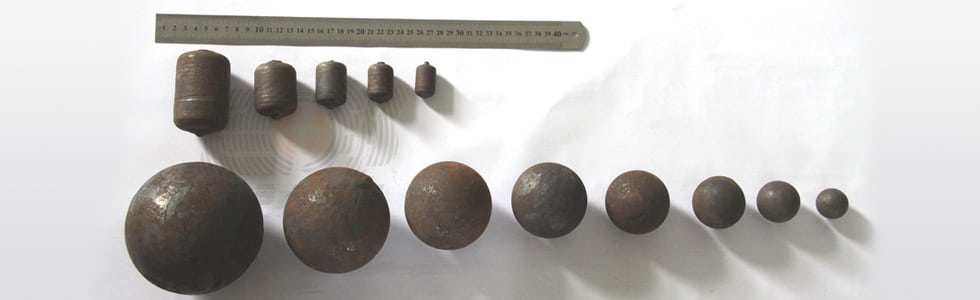

grinding media ball machine,Grinding Cylpebs

5. Remelting and return to the furnace: During the whole rolling process, there will be some waste steel balls and residual billets. These materials will not be wasted, but will be remelted and reused.

This working process is cyclically repeated. A wear-resistant steel ball skew rolling mill can continuously produce high-quality wear-resistant steel balls during operation.

Leave a Reply

Want to join the discussion?Feel free to contribute!