The Processes of Matching the Proper Grinding Balls for Ball Grinder

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com)

Email: info@skewrollingmill.com

facebook: https://www.facebook.com/skewrollingmill

youtube: https://www.youtube.com/user/skewrollingmachine

Pinterest: https://www.pinterest.com/skewrolling

Blogs: http://www.skewrollingmill.blogspot.com

The grinding ball is a material grinding media of ball mill and coal mill. Its’ function is as an important component of ball mill under grinding and cutting effect brought by the friction between grinding balls and materials.Therefore,let’s talk about the processes of matching the proper grinding balls for ball grinder.

1. With effective surface area of steel balls to measure the rationality of the steel ball ratio. A warehouse in effective surface area of steel balls should achieve every ton of steel balls 9.5-10.5 m2. For with the roller press of closed circuit ball mill, this value can be adjusted for 12 m2/t, and the liner plate is continuous ascension type. The balls in the specific surface area should be 35-38 m2/t, belt roller pressure unit for 38-40 m2/t. The ratio of specific various balls diameter still according to the maximum stacking density calculation.

2.Generally, the load rate is 25% -35% in the filling space of abrasion resistance steel balls, the lower loading rate of steel ball, the less of power consumption, and the productivity is getting low. Therefore, the primary prerequisite of the total count of adding grinding media is that the ball weight and the weight of the material in the mills is less than the allowable value and close to the ball mill motor power.

3. Conforming to the loading principle on grinding balls in the main warehouse. The size of feeding clinker particle in the first warehouse is not more than 30 mm, so it’s main function is broken, and the diameter of Steel balls loaded should be in 50 between 90 mm. When into the second warehouse of ball grinding mill, the clinker are less than 2-3 mm, so it is the function of fine grinding, steel balls’ range in this warehouse should be 15-50 mm.

4. Computing unit ball production to verify the rationality of the match ball.

5. Determining the maximum diameter of the grinding media.

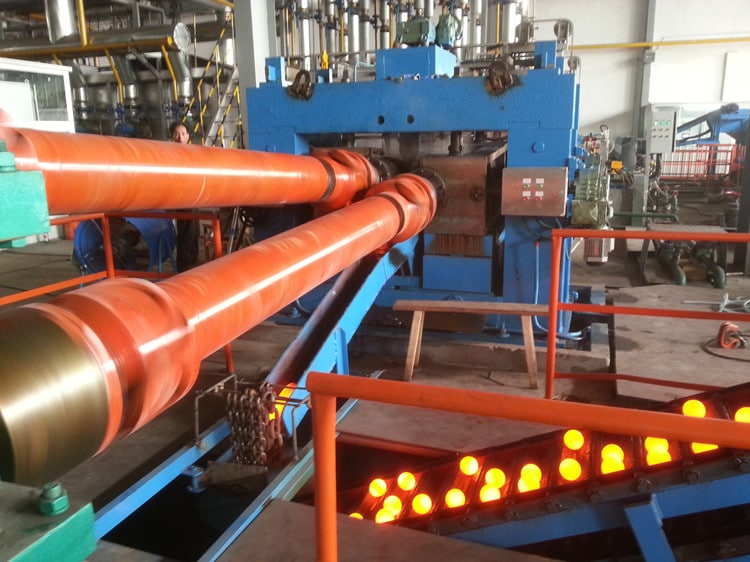

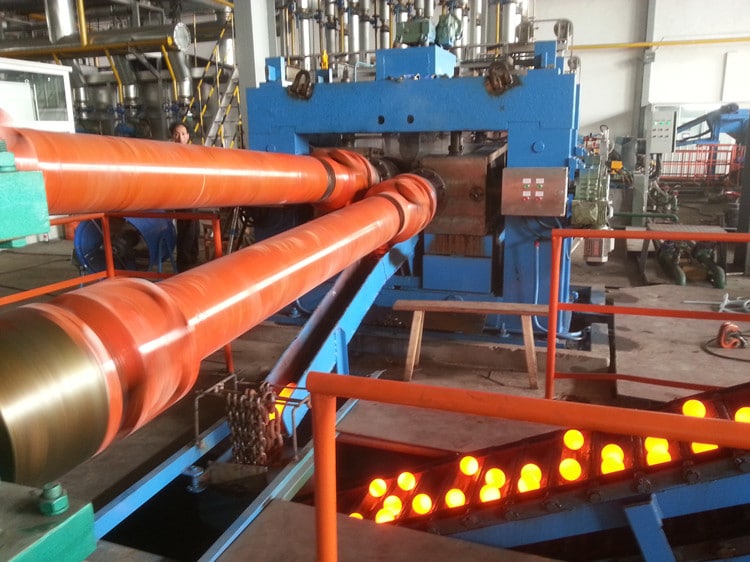

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com) is a professional skew rolling mill manufacturer in China, the diameter of our steel balls span from 20mm-150mm. Priorities of our steel balls: High hardness, good wear resistance, breakage rate lower than 0.5%, no deformation all through.