Tag Archive for: skew rolling mill

What is the Grinding steel Ball(casting and skew rolling)

Grinding ball material mostly are alumina and zirconia which…

The key factors of performance of grinding steel ball

The key factor of grinding steel ball's lifespan decided by its…

Ball Mill Effects in Mineral Processing

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com)

Email:…

Dry Ball Mill Introduction

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com)

Email:…

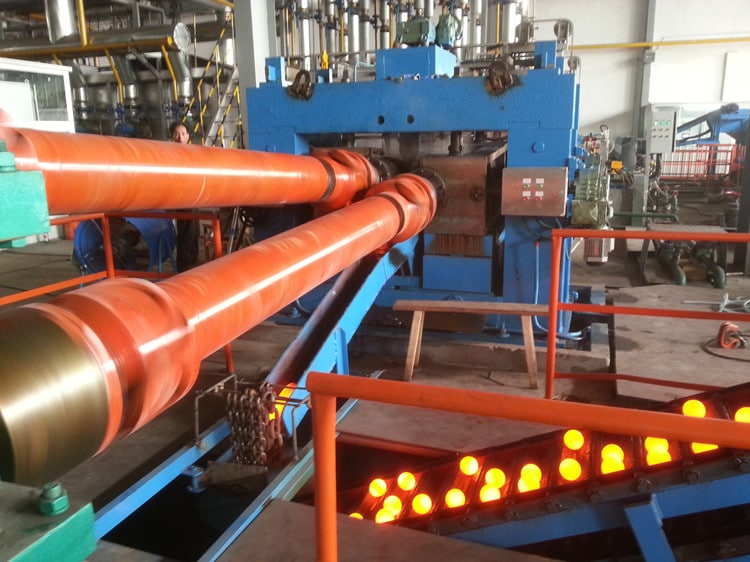

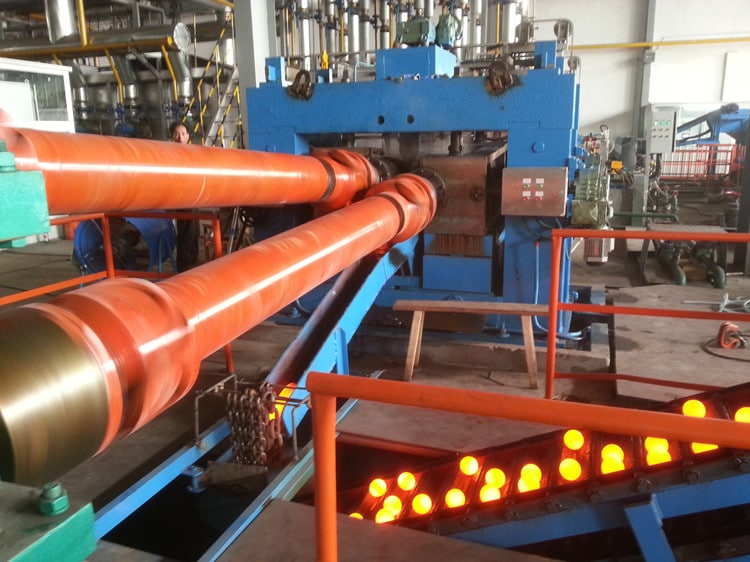

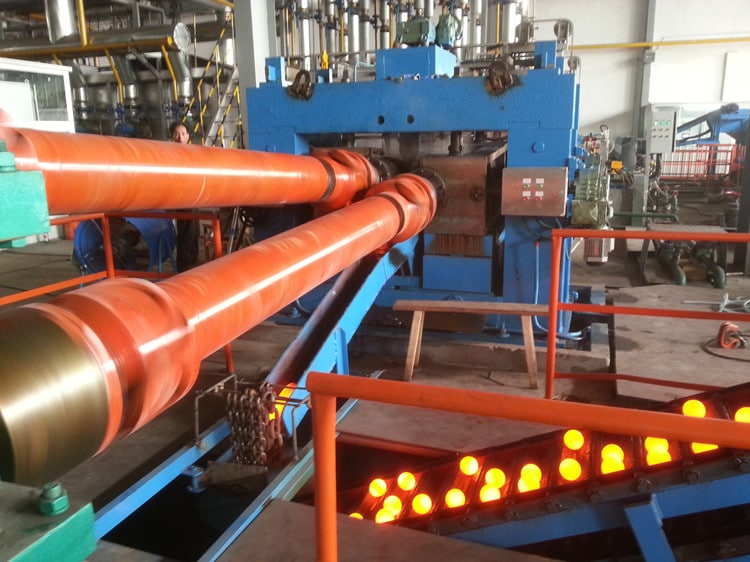

Main processes of hot rolling grinding balls as follows

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com)

Email: info@skewrollingmill.com

facebook:…

Steel billet for skew rolling steel ball

1.The chemical composition range of the steel rod which are…

Grinding steel ball overview

Hot-rolled steel ball(Grinding steel ball) which are rolled by…

LT – B3 hot rolled steel billet for skew rolling mill

LT - B3 hot rolled round steel technical agreementRangThe…

Drawbacks of the Casting steel ball

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com)

Email:…

The Processes of Matching the Proper Grinding Balls for Ball Grinder

Suchuang Machinery Equipment Co., Ltd(http://skewrollingmill.com)Email:…